What is Spray Foam Insulation?

Spray foam insulation (SPF), or spray polyurethane foam, is one of the most energy-efficient and cost-effective solutions for residential and commercial buildings. Whether you’re working with new construction or upgrading an existing structure — from metal buildings to barns — spray foam helps your building perform as a complete system. When applied to walls, roofs, ceilings, floors, basements, and foundations, it minimizes air leaks and keeps conditioned air inside where it belongs. SPF is a powerful 2-in-1 solution, serving as both a high-performance insulator and a superior air barrier.

Tax Credits, Rebates, & Savings – find out what is available in your area from Energy.gov

Recommended Levels of Insulation – brought to you by Energy Star

Why Spray Foam Insulation?

Understanding R-Values

R-value measures how well a material resists heat transfer. It reflects the thermal resistance of insulation — the higher the R-value, the better its insulating performance. Keep in mind, actual effectiveness can vary depending on the type of construction and the heating or cooling system in place.

Click here to see recommended Home Insulation R-Values

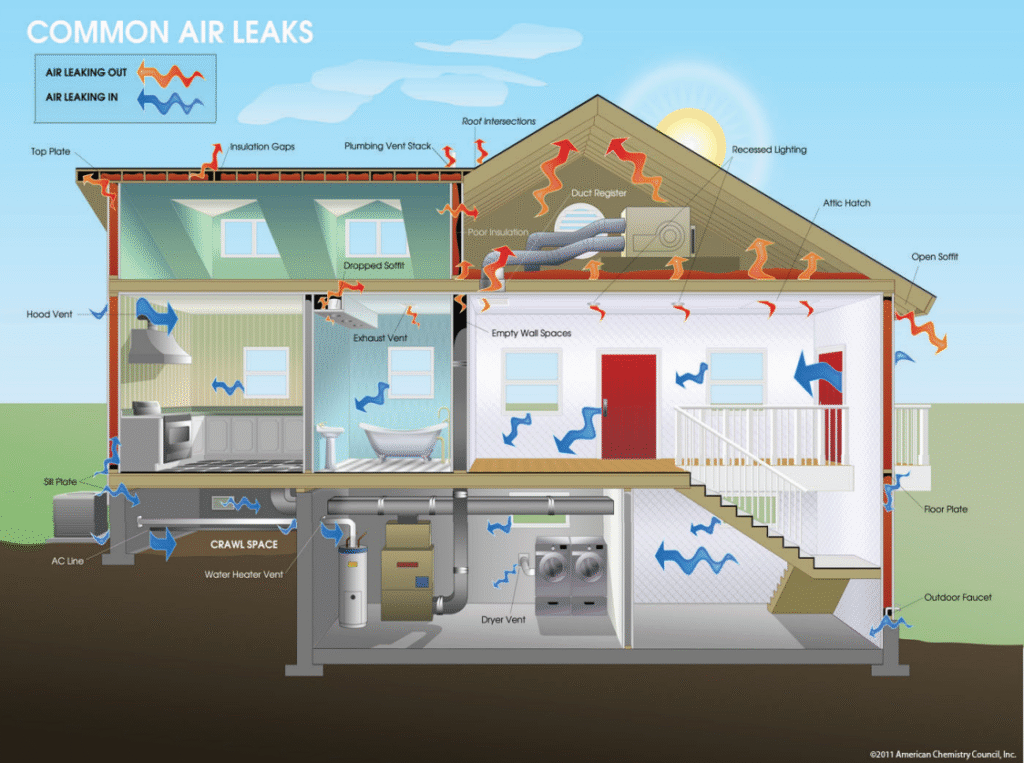

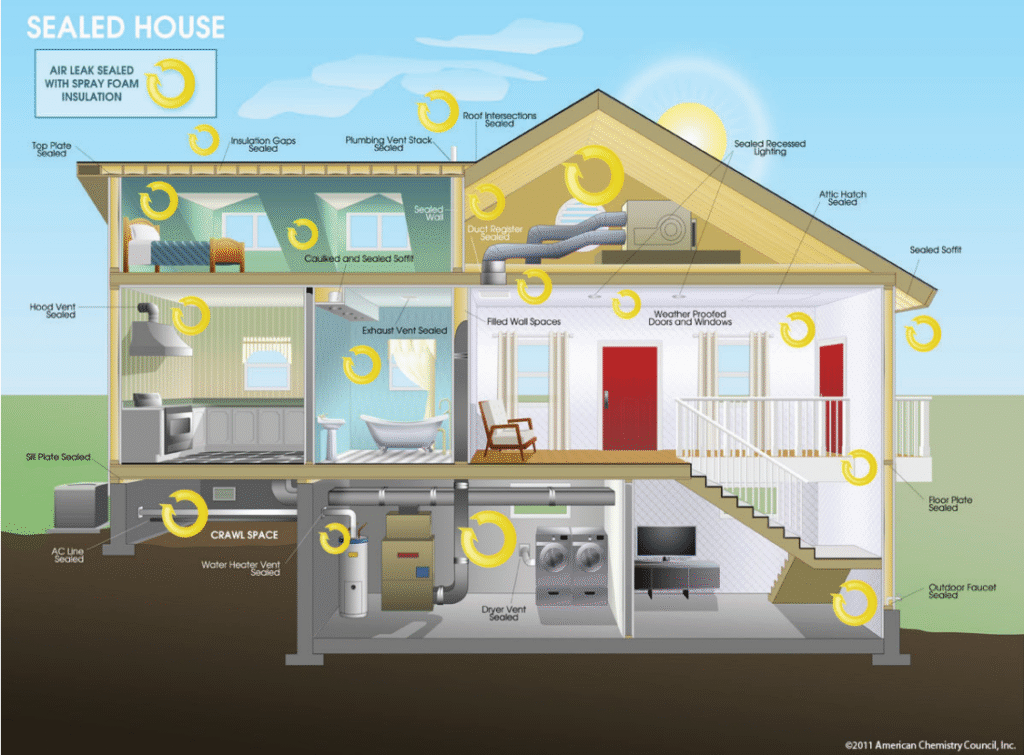

Common Air Leaks vs a Sealed House

Up to 40% of a building’s energy is lost through air leaks, driving up utility costs. Spray foam acts as both insulation and an air barrier, sealing gaps and reducing energy waste. The EPA estimates that heating and cooling account for nearly half of a home’s energy use. By improving efficiency, spray foam can reduce HVAC sizing by up to 35%.

Spray foam effectively seals common leak areas such as attic hatches, knee walls, wiring holes, plumbing vents, recessed lights, rim joists, and around windows and doors.

Spray foam can also enhance “cool roof” performance when topped with a reflective coating. These roofs reflect sunlight, stay cooler, and reduce heat gain—without the need for metal fasteners that create thermal bridges.

Adapted from WhySprayFoam.org’s publication entitled “Why Choose Spray Foam?” – Downloadable here: https://www.whysprayfoam.org/wp-content/uploads/2021/09/Why-Choose-Spray-Foam.pdf

Encapsulating Your Crawl Space

Why Encapsulate a Crawl Space?

Crawl space encapsulation involves sealing the area beneath your home from external elements. This process typically includes installing a vapor barrier along the floor and walls, as well as sealing vents and other openings. Spray Foam Insulation provides the preferred vapor barrier.

Encapsulation offers several key benefits:

1. Better Indoor Air Quality

Crawl spaces often harbor moisture, leading to mold and mildew growth. These contaminants can infiltrate your home’s air, potentially causing health issues. By encapsulating the space, you reduce moisture and block harmful pollutants from entering your living areas, resulting in cleaner, healthier air.

2. Enhanced Energy Efficiency

Unsealed crawl spaces are common sources of energy loss due to lack of insulation. This allows warm air to escape in winter and cool air in summer, making your HVAC system work harder. Encapsulation helps maintain a consistent indoor temperature, lowering energy consumption and utility bills.

3. Pest Prevention

Dark, damp crawl spaces attract pests like rodents and insects. Encapsulation seals entry points and eliminates the moist conditions pests thrive in, reducing the risk of infestation and protecting your home from related damage.

4. Increased Structural Longevity

Moisture in crawl spaces can deteriorate wooden structural components over time, leading to costly repairs. Keeping the space dry with encapsulation helps preserve the integrity of your home’s foundation and supports long-term durability.

Conclusion

Encapsulating your crawl space is a smart investment that improves air quality, boosts energy efficiency, deters pests, and protects your home’s structure. It’s a proactive step toward a healthier, more comfortable, and longer-lasting home. Give us a call for an estimate to encapsulate your crawl space.

Spray Foam Insulation Information:

Spray foam insulation is an alternative to traditional building insulation, such as fiberglass. It is a two-component mixture composed of isocyanate and polyol resin that come together at the tip of a gun and forms an expanding foam. The foam can be sprayed onto roof tiles, concrete slabs, into wall cavities, or through holes drilled into the cavity of a finished wall. Both types of SPF are thermoset cellular plastics comprising millions of small cells. There are two different types of spray foam insulation:

Light-Density Open Cell (half pound foam):

- Due to its ability to expand during the application process, OC SPF fills cracks, crevices, and voids and adheres to irregular surfaces or substrates to form an air sealing insulation.

- It provides sound reduction by blocking and absorbing air leakage.

- Reduces noise transmission.

- Semi-rigid material with a sponge-like appearance that expands during installation and creates small, open cells that are filled with carbon dioxide. It can be crushed in your hand.

- It is less expensive than traditional types of insulation such as fiberglass.

- OC SPF has a typical R-value of 3.5 to 3.7 per inch.

- It is usually only recommended for indoor applications.

- We normally do not recommend using open cell foam in the Pacific Northwest.

Closed Cell (aka two-pound foam):

- CC SPF creates an airtight barrier. When the required minimum thickness of 1.5-2 inches is installed, CC SPF is both a vapor barrier and an air barrier.

- It is perfect for attics, exterior walls, and metal buildings.

- Reduces noise transmission.

- A moisture barrier is created.

- It is rigid to the touch

- Adds strength and rigidity for improved structural integrity.

- There is a typical R-value of 6 per inch.